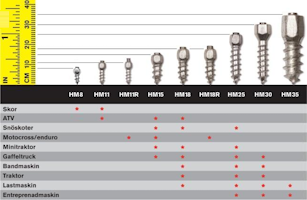

MaxiGrip®-dubben är en patenterad svensk skruvdubb för självmontage som är avsedd för terräng- och arbetsfordon samt skor.

Den enkla monteringen sker snabbt med vårt patenterade verktyg och en vanlig skruvdragare. Demonteringen sker precis lika lätt.

Med MaxiGrip®-dubben får du säkert grepp i alla vinterväglag oavsett om du går eller kör ett fordon.